Our Key Services

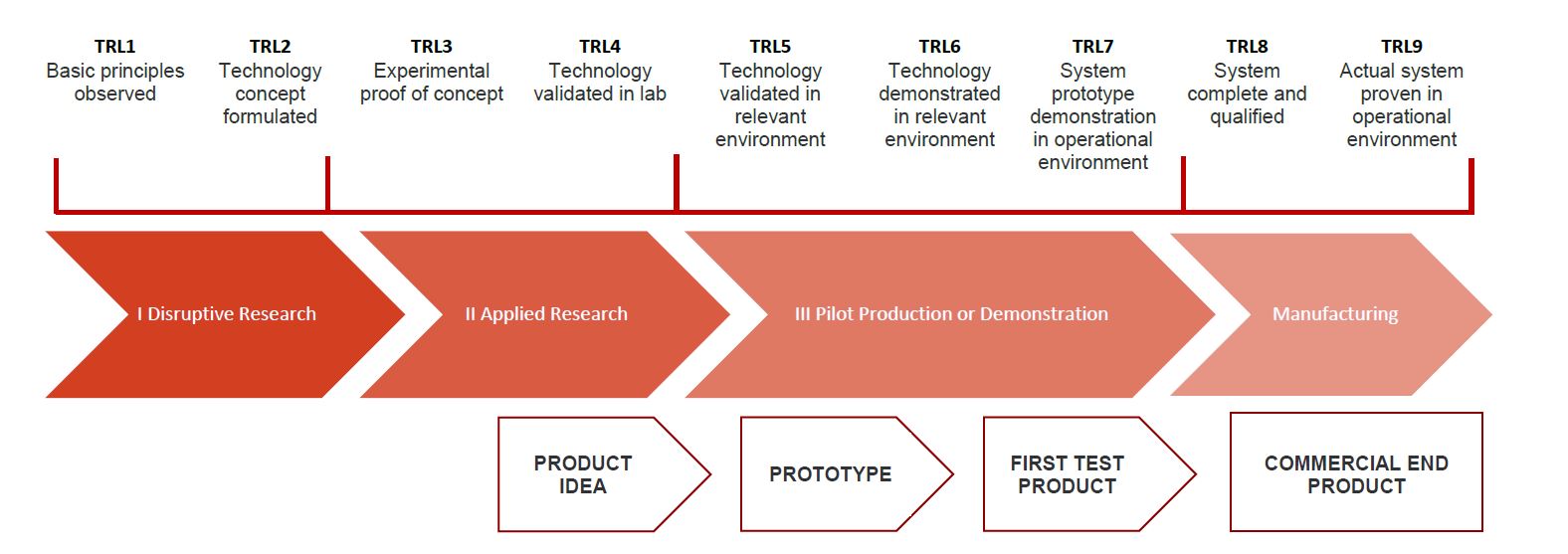

NASA developed Technology Readiness Levels (TRLs) in the early 1970s as a means of assessing whether emerging technology was suitable for space exploration. By the 1990s, it was in use across many US Government agencies, including the Department of Defence (DOD) and the Department of Energy (DOE). TRLs are now in common use across various funding programmes, including Innovate UK and Horizon Europe. The different levels are based on a scale from 1 to 9, with 9 representing the most mature technology:

The use of TRLs enables consistent, uniform discussions of technical maturity across different types of technology. There are some key messages to remember:

External Factors

TRLs are a measure of technical risk. However, by themselves, they may not relate to risks, cost and schedule. For instance, a technology at a low TRL can mature more quickly than those at higher TRLs. In addition, if the project environment changes, it is also possible that TRLs will go down as well as up. Therefore, you should analyse your TRLs with care and consider the external factors that might affect them.

External Factors

TRLs are a measure of technical risk. However, by themselves, they may not relate to risks, cost and schedule. For instance, a technology at a low TRL can mature more quickly than those at higher TRLs. In addition, if the project environment changes, it is also possible that TRLs will go down as well as up. Therefore, you should analyse your TRLs with care and consider the external factors that might affect them.

Technology Readiness Levels

TRLs relate to individual plant items they do not suggest that the individual plant items can be integrated and will work together. When it comes to R&D funding, then, it is possible that the innovative technology is actually the sum of different individual items. A valuable suggestion would be to assess the TRLs of each of the parts composing the technology.

TRLs Cannot Indicate Eligibility

Remember, TRLs indicate how far the technology is from commercialisation; they do NOT indicate, on their own, whether it is eligible for a funding application. Other factors, including scope, are also important. When you approach a funding competition, we’d advise that you read the scope first and use TRLs to support your application.

Grant Matcher

Discover UK grants now available to help your business grow.

Our simple to use grant matcher tool allows you to choose your region, sector and business type to help narrow your search.

Grant Matcher

Discover UK grants now available to help your business grow

Our simple to use grant matcher tool allows you to choose your region, sector and business type to help narrow your search.